East Iowa Plastics is a diversified, custom plastics processor. We specialize in prototyping, design, fabrication and finishing of thermoformed and injection molded products. We also prototype products for other forms of manufacturing. We serve clients, large and small, in consumer and industrial markets.

plastics processor. We specialize in prototyping, design, fabrication and finishing of thermoformed and injection molded products. We also prototype products for other forms of manufacturing. We serve clients, large and small, in consumer and industrial markets.

Our manufacturing process includes the use of several types of plastic: high impact polystyrene (HIPS), high and low density polyethylene, high molecular weight polyethylene, ABS, co-extruded ABS and HIPS with an acrylic KORAD cap sheet stock, and polycarbonate, to name a few. We are capable of forming thin to thick gauge parts and are currently forming parts with a starting gauge of .350" and a 5.1 draw ratio.

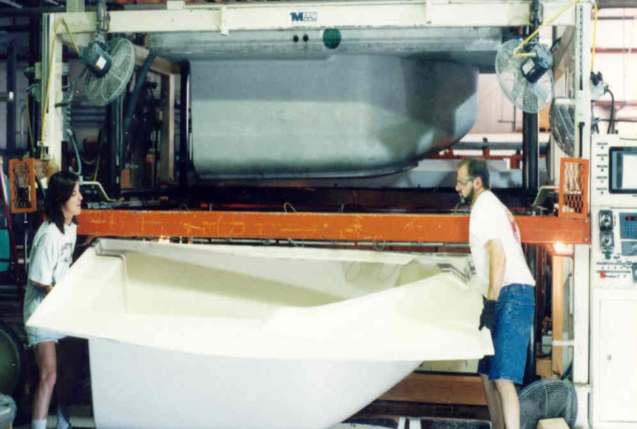

East Iowa Plastics maintains a production plant of 30,000 square feet, with a 15,000 square feet warehouse with shipping and receiving. We provide three shifts of production employees on a seven day a week basis. Our capabilities range from prototypes and low volume runs, to unlimited large volume runs; from simple to complex, and small to large parts. Fabricating operations include trim presses, routing, punching, sonic welding, solvent welding and additional assembling and finishing stations.

Quality workmanship is important to our company in all our products. East Iowa Plastics constantly examines the production process, as well as material selection, molding, testing, and custom designed packaging for transporting the finished product. Statistical Process Control (SPC) has become an important part of normal production to facilitate high standards of achievement through the entire manufacturing process.

Our dedicated staff provides customers with the highest quality products when they need them, and at the lowest possible cost. EDI capability and a manifest shipping system allows communication with our customers to meet individual shipping needs. We negotiate the best possible rates with local transport companies, discounts being in excess of 60% for some carriers. It's important every customer have confidence in both our product and our service.

At East Iowa Plastics, we are committed to manufacturing quality products, which enable our customers, as well as ourselves, to meet the challenges of an increasingly competitive marketplace.

• EQUIPMENT •

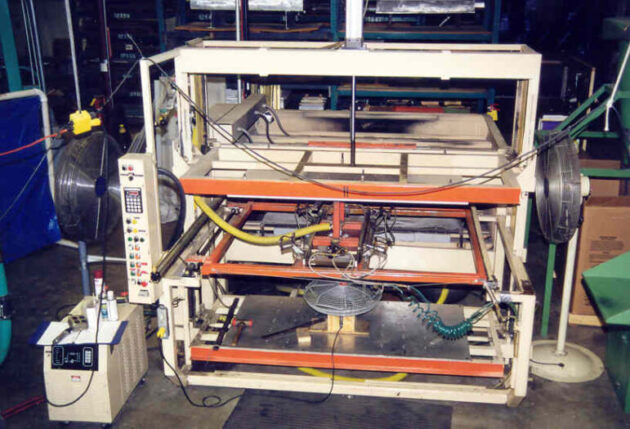

Single Station Unit forming parts up to 48" x 60" with a top draw depth of 36" and bottom depth of 24".

Three station rotary unit forming parts up to 48" x 80" with a top and bottom draw depth up to 24".

Large single station capable of forming parts 96" x 120" with a top draw depth of 48" and a bottom draw depth of 46".

Continuous feed, inline thermoformer integrated with a 3 1/2" extruder and roll stack, capable of extruding a sheet 24" wide and up to .050" thick at 2,000 parts per hour.

220 ton Injection Molding Machine, 20 oz. shot capacity; long or short run.

3-axis Thermwood CNC router, capable of low profile routing, milling and drilling.

5-axis Quintax CNC router, capable of extensive three dimensional milling and machining of larger parts and molds.